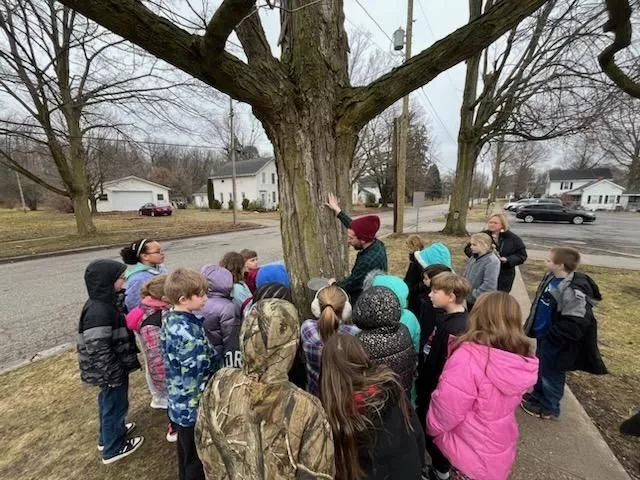

The X-Box Generation got a peek behind the curtain today at one of the most sophisticated manufacturing plants in all of Michigan’s Great Southwest thanks to the efforts of Team Kinexus and their robust week-long performance as hosts of not only Manufacturing Day, but their conversion to Manufacturing Week all week long as well.

Nobody is happier about that than Vickers Engineering President & CEO Matt Tyler. As more than five dozen students from schools across the landscape participated in each of several plant floor tours this morning at his facility in New Troy, Tyler took a few moments to share his thoughts and perceptions about the 6th Annual Manufacturing Day in general, and his facility in particular.

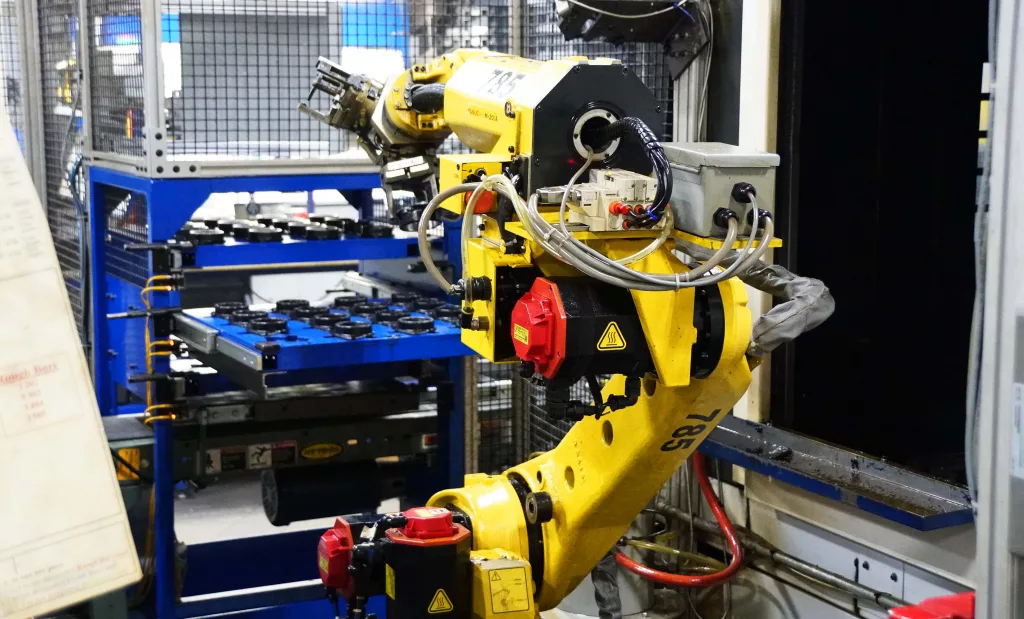

Asked why Vickers is so overwhelmingly on board with the program, Tyler says, “We see that the opportunity in this country, and specifically in this particular area in Southwest Michigan, for manufacturing is unbelievable. Manufacturing has grown by leaps and bounds, and we’ve grown significantly here just at Vickers, in the use of technology, automation and robotics.”

For some, when you say robotics, you might as well be saying job elimination. The popular misconception is that automation takes jobs away. Matt Tyler argues, “That couldn’t be further from the truth — automation taking jobs. That’s like somebody arguing that lawnmowers replaced guys in fields with sickles, it just doesn’t make sense. We’ve not only added jobs – in the past 10 years we’ve added from 170 to 195 people — but the jobs are completely different, having replaced jobs that nobody wanted.” In fact, Tyler will tell you, “Our payroll has doubled in that time!” By way of explanation, the Vickers team leader says, “To give you perspective, the average wage on the floor is significantly greater than it was. I can’t stress enough that we’re replacing jobs that nobody wanted, but now we’re globally competitive.”

Reality is that by embracing technology, automation and robotics, Vickers is growing exponentially. Tyler says, “We’re winning work that is currently done overseas and it’s coming back here to Southwest Michigan and creating highly paid jobs, and highly sophisticated technical jobs that have a huge upside of growth from there.”

Another reality is that those who fail to adapt to the changing world are the ones being left behind. As Tyler points out, “Automation is becoming a must in manufacturing, and when China is buying three times as many robots as the United States, what does that tell you? So, we are in the game. Vickers is extremely automated and we’re actually a leader in our field, and we’re looking for bright young talent to keep the pipeline going. We need that.”

The plant floor at Vickers, and for that matter many other manufacturing facilities in Southwest Michigan, does not match up with the general public’s view of manufacturing. As a result, Tyler contends, “We need to expose kids to this work. These are careers that are unbelievably important not only to our economy, but they offer a lot more potential than most people expect, and I’m telling you, it’s not only here to stay, but it’s going to grow significantly in the next 5, 10, 15 years.”

As Tyler and his team watched the scores of students craning necks to check out bright yellow robotic arms performing multiple functions on the shop floor, he suggested, “We need this younger generation in here. It’s the X-Box Generation. We need people focused on technology — who understand the technology — and if we can solve that need of ‘how do we create a labor force,’ the jobs are going to be there. So, the race is on in that regard.”

I asked Tyler what he sees when students from all manner of schools show up on his doorstep for Manufacturing Day. His answer might surprise you, as he says, “I think the biggest thing — and we get comments even from current customers who are shocked at the amount of technology on our floor — a lot of the kids that come through are a little surprised, but we are incredibly impressed with the sophistication of the questions that we get from them. It’s really encouraging. They’re here asking very appropriate questions on ‘What does this career look like? What am I going to be doing? What next steps can I take?’ They’re savvy, and it’s pretty neat to see.” In contrast, the highly successful Vickers captain says, “I remember when I was that age, I probably would have just strolled through and had no clue what I was looking at, while for the most part we’re getting a lot of kids that are asking very pointed questions. It’s impressive.”

But what about the parents? What does Tyler hear from them? Matt says, “Parents’ perceptions of a dirty shop floor are often one of the biggest barriers. I remember a few years ago we acquired some kids that were really interested in working here, and we said, ‘Hey bring your mom,’ and they all kind of laughed and we said, ‘No, we’re not kidding,’ and whenever that did occur, we had a wonderful result from it, because it did cut through that traditional stereotype of a dark, dirty, unsafe, plant floor, which couldn’t be further from the truth, and that’s important.”

Tyler says there are two levels of stereotype they seem to get, telling us, “One is certainly the kids and educating them on what’s going on, but the parents that drive by the facilities every day that they’ve seen for years, they don’t understand the transformation that has gone on behind those walls. We’re struggling to figure out how to expose them to that, to tell the real story, but I think we’re making good progress and its days like today.”

Tyler says, “The more we can do — and you being here right now is extremely helpful — because, it’s important for our economy and for all the businesses out there, because manufacturing is the base of any great economy and we have that capability not only here in SW Michigan, but Michigan in general, and throughout the Midwest because it’s coming and it’s been building, and building, and building over the years.”

Tyler says at Vickers, “The forecasts we see are unbelievable. We have more quoting activity — for years to come — and more than we’ve ever seen before, and a lot of it is because of what’s going on in the country and all this manufacturing talk, so it’s extremely positive and we’ve got to capitalize on that.” Vickers parts are now in virtually every Toyota vehicle in the line up…and increasingly in Honda, Subaru and other brands. That’s an extreme point of pride for Tyler and his crew.

Today was another great day of eye-opening information at Vickers for both the manufacturers and students alike, for which they are all grateful to Team Kinexus and everyone who helps make Manufacturing Day and Manufacturing Week a true turning point. Just seconds before hitting the shop floor with another flight of students, Matt Tyler turns to me and say, “The future is bright for the students and for Vickers and that’s good stuff! So let’s keep the train rolling!”