The ability to acquire top-flight talent at Hanson Mold in St. Joseph has been legendary through the years, and the company’s opportunity to promote from within through that homegrown talent bank continues to set the stage for continued growth and success, as witnessed in three major promotions in the house in recent weeks.

Hanson Mold President Dan Mitchell tells us that Chip Spear has been promoted to Vice President of Manufacturing, Julie LaVanway advances to the role of Vice President and Chief Financial Officer, and Brian Liggett has earned promotion to Sales Project Engineer for the St. Joseph manufacturing firm.

Mitchell says, “We are very fortunate to have a great team at Hanson Mold and Brian, Julie and Chip have been great examples of that for us. All three of them have made an impact at Hanson Mold, not only helping us to be a better company today, but I am confident that they will all be a driving force for us in the future.”

Chip Spear was previously Plant Manager for Hanson Mold. He joined the company in 1993, and advanced to Manufacturing Supervisor in 2001, a position he held for 18 years before being promoted to Plant Manager in 2019. During his tenure, Chip has implemented protocols which have improved efficiency throughout several departments in manufacturing.

Julie LaVanway was previously Controller at Hanson Mold. She graduated from Andrews University in Berrien Springs with a degree in Accounting and Finance, and previously worked as an Accounting Manager within the Hanson Group of companies for 7 years.  Prior to that she was a Financial Auditor for 5 years. Mitchell says that Julie brings extensive experience in the financial realm which has shown in her ability to make key decisions for the company.

Prior to that she was a Financial Auditor for 5 years. Mitchell says that Julie brings extensive experience in the financial realm which has shown in her ability to make key decisions for the company.

Brian Liggett was previously a Manufacturing Supervisor for Hanson. He has been with the company for more than 23 years. He graduated from Sienna Heights University with a degree in Business.  Mitchell says that Brian brings a wealth of talent and knowledge of die cast die manufacturing to the sales department, and adds, “His experience will allow him to excel in customer service, solutions, and communication.”

Mitchell says that Brian brings a wealth of talent and knowledge of die cast die manufacturing to the sales department, and adds, “His experience will allow him to excel in customer service, solutions, and communication.”

Hanson Mold, a division of the Hanson Group, was founded in 1966. The company’s name comes from Founder and Chairman of the Board, Merlin Hanson, a tool and die apprentice graduate himself. The Hanson Mold facilities, located on a 50-acre site along Hollywood Road in St. Joseph, consist of an office and engineering group, a 42,000 square foot tooling facility, and a 10,000 square foot mold testing facility.

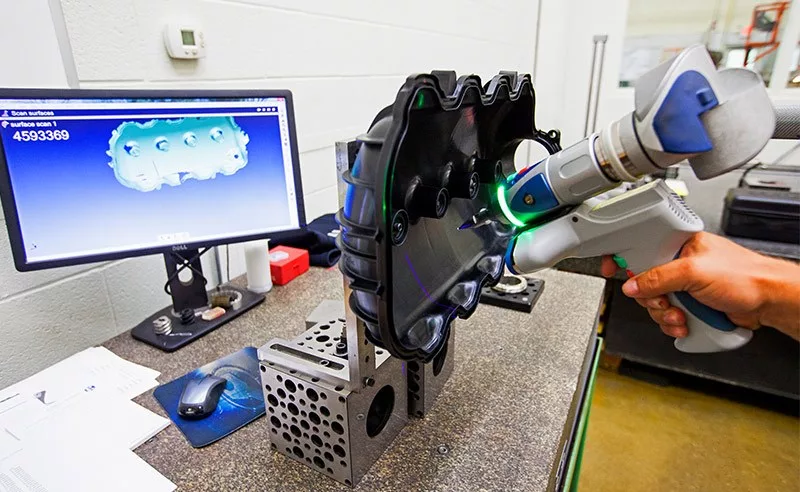

Hanson Mold specializes in the design, build, sample, and inspection of precision molds – primarily for the die cast industry. Using modern equipment and engineering/design software, the Hanson team has always been committed to providing the die cast industry with the finest, most efficiently designed, high quality, long lasting tooling available. From small, multi-cavity dies to large, single-cavity tooling with complex slides, Hanson Mold ensures every client a world class tool.

The 55 year old company offers complete die design, construction, sampling, and inspection of zinc, magnesium and aluminum die cast dies, all driven by a dedicated team of associates many of which have been with the company for years, side-by-side with new recruits through a vigorous apprenticeship program continually in search of new world-class talent.

Learn more about the company, its people, products, and career opportunities by clicking this link: https://www.hansonmold.com/